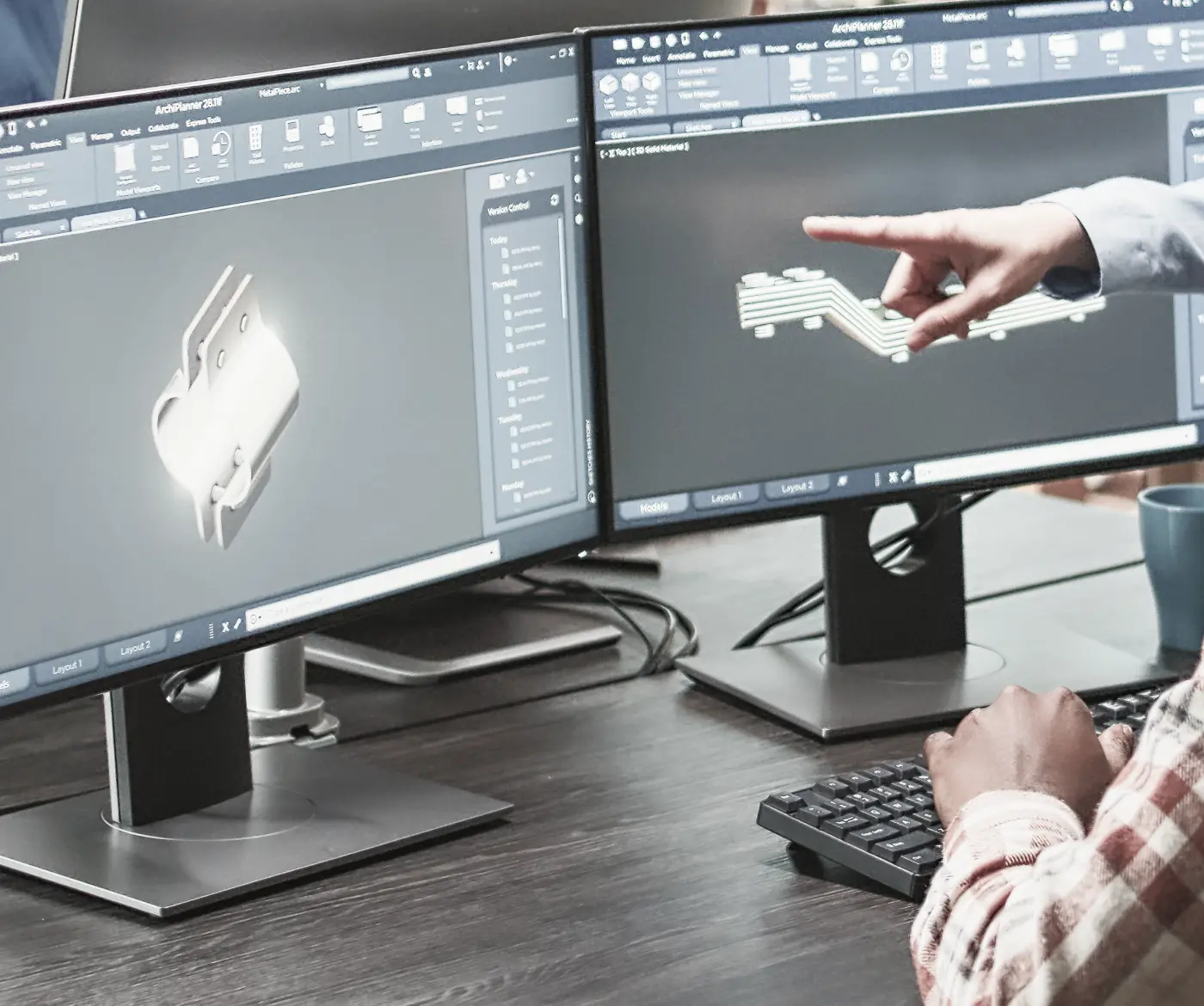

Our Prototyping

Capabilities

We offer a comprehensive suite of prototyping technologies to suit your specific project needs. Unlike service providers who offer a single solution, we provide multiple options to find the best fit for your design goals and budget.

3D Printing

We position 3D printing as an efficient tool for rapid iteration and creating functional prototypes. It's a key part of our process for quickly validating designs.

CNC Machining

We use advanced CNC machining to create high-precision, robust prototypes from a wide range of materials.

Why Start With Our Prototyping Services?

Our integrated approach eliminates the common frustration of working with multiple, disconnected companies.

When you partner with us, your project moves seamlessly from the design phase to prototyping with a team that already understands your vision and goals.

The Prototyping Advantage

Prototyping is a bridge between the Design and Manufacturing phases. A successful prototype allows you to:

Test functionality

Use your prototype to confirm that your product works as intended in real-world scenarios.

Identify flaws

Catch design issues early, which is significantly more cost-effective than discovering them during the manufacturing phase.

Attract investors

A high-fidelity prototype can be a powerful tool for demonstrating your product's viability to potential investors or partners.

Test functionality

Use your prototype to confirm that your product works as intended in real-world scenarios.

Identify flaws

Catch design issues early, which is significantly more cost-effective than discovering them during the manufacturing phase.

Attract investors

A high-fidelity prototype can be a powerful tool for demonstrating your product's viability to potential investors or partners.

Ready to Scale from Prototype to Production?

Explore our manufacturing services to move your validated design to full-scale production.

EXPLORE MANUFACTUING SOLUTIONS